A2E Services

Product Development

Full Product Lifecycle

No matter your product idea, A2E can provide the expertise to bring it to realisation. From the initial steps of Requirements Capture and Concept Generation through Detailed Design. We focus on meeting your needs to deliver the required functionality while considering product cost and human factors.

We can deliver prototypes along the way to help with business development and advance the design testing.

Taking the next steps along the development path, we work closely with manufacturing engineers at the factory and key suppliers to ensure the product design optimises manufacturability, assembly, and testing and meets the necessary regulatory requirements.

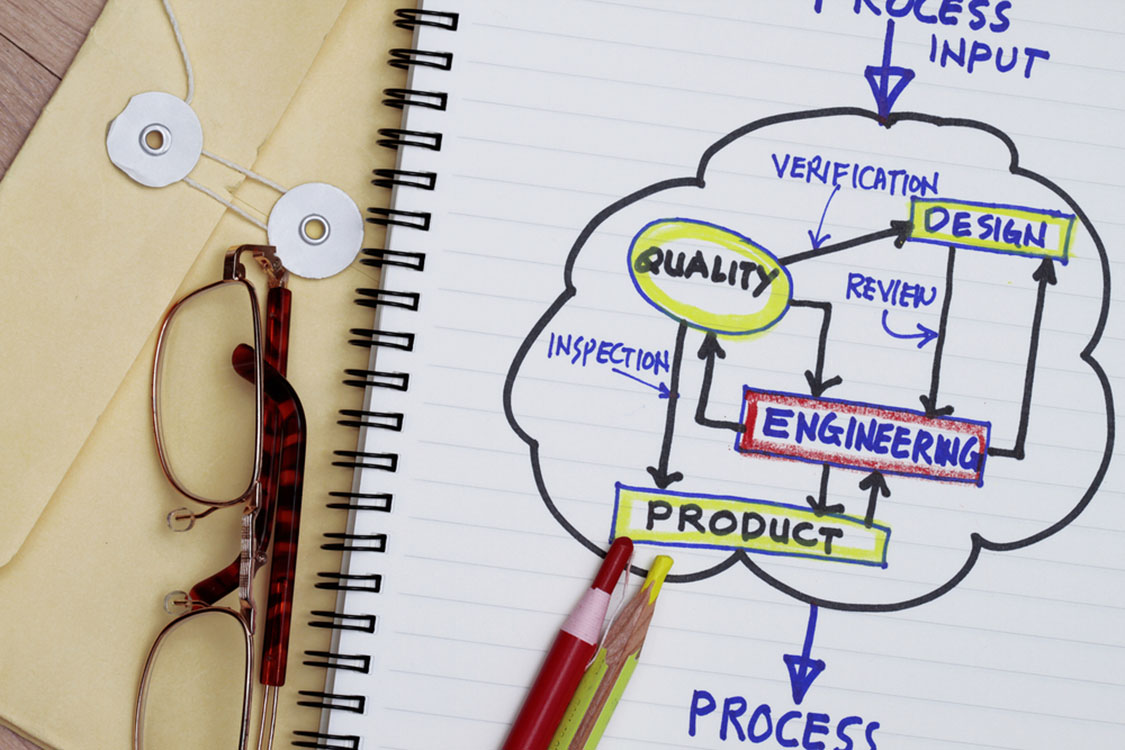

All of these activities are overseen closely by our team of experienced project managers, keeping the schedule and costs under control whilst ensuring that our quality principles are at the forefront of the work.

Project Management

A2E’s project management team supports your project throughout its entire lifetime, from conception to manufacturing. Our team has over 20 years of experience designing and launching a wide array of products with our customers. We assist and personally guide our customers during every stage of the project. We utilize a well-defined process and ISO:9001 Quality Management System to ensure the results meet the demands of your project.

At every step, our project managers will help you set and meet project goals and deliverables, regulate your product’s manufacturing outputs, and determine your project’s budget constraints. Whether it be feasibility studies, prototype development, or complete volume manufacture and testing, A2E can develop and differentiate your products to move them to market quickly and efficiently.

Product Feasibility and Prototyping

In collaboration with our sister company, Wideblue, we are able to complement our design services portfolio with industrial and mechanical design expertise. Using SOLIDWORKS 3D CAD, our mechanical design teams have extensive knowledge of a broad range of product applications and can deliver designs from concept sketches to volume manufacturing. Designs are further strengthened by engineering calculations and simulation capabilities, including stress analysis (FEA) and fluid/thermal simulations (CFD).

A2E specialises in detailed feasibility studies to give you a complete picture of the project before you begin. Before committing to the full development of your product or project, we use our expertise to investigate technologies and advise you on potential solutions, timelines, and cost estimates. We may recommend starting with a prototype.

We have unique experience in electronics, firmware and software that makes us the perfect partner for your scientific product development. We understand that precision, reliability, and accuracy are paramount from data analysis to system control.

We have developed products in application areas from particle physics research to astronomical study through spectroscopy and colourimetry. Our strengths are further enhanced when combined with our sister company's optical physics and mechanical design capabilities, Wideblue.

Developing a prototype design offers an early opportunity to test a concept, engage with potential customers, and gain valuable information before committing to a full design. We are experts in developing physical “proof-of-concept” products. Our prototypes can help leverage investor financing, encourage management buy-in on a project, or discover and define critical project flaws. Often, components can be swapped in/out to try out new ideas before settling on the final solution.

By ensuring the required precision, accuracy and reliability are included early on, you can leverage the prototype delivery to increase your Technology Readiness Level (TRL) and start to gather knowledge about how your product operates in real-world environments.

Our prototypes are designed to enable rapid advancing progress to a pre-production system and volume manufacturing — we’ve delivered detailed designs from prototype to dedicated engineering samples in as little as eight weeks.

Product Realisation

At A2E, our focus is on quickly, efficiently, and successfully realising products for our customers.

We have the abilities to cover the entire process, starting from the customer product concept. We perform feasibility studies and prototyping, defining specifications, designing the mechanics, electronics and software, implementing the design, testing, assisting the customer with certification, and performing the transfer to volume manufacture.

When the customer prefers to manage the overall product realisation, we are also happy to assist with individual steps throughout the process.

We have experience in a wide range of industries and enjoy technically challenging projects.

Product Testing

A2E has over twenty years of experience in delivering testing solutions to meet a variety of customer and product requirements, ranging from design validation, design fault finding, certification, accreditation, and field trials.

We have experience in product handover to the factory and can help develop testing procedures for the production cycle, from board level, quality control, system, and functionality, to customer acceptance tests and test planning.